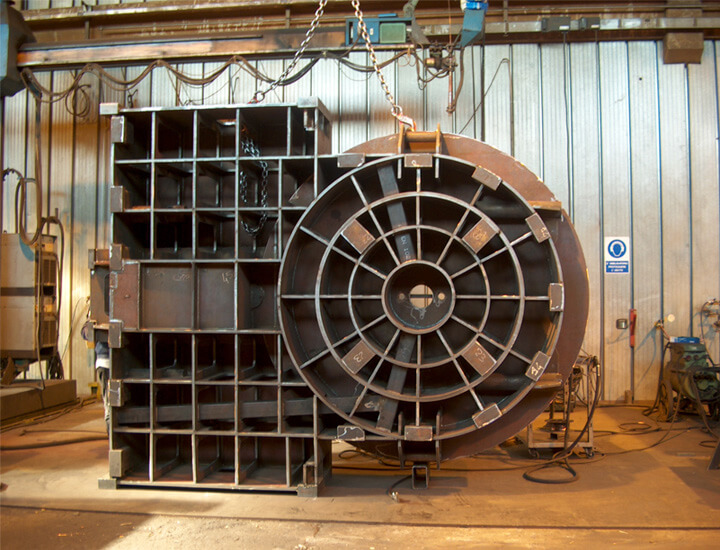

Mechanical Carpentry

We are experts in the construction of electrowelded structures for machinery and installations

Qualified personnel

The professionalism, experience and specialisation of each member of our department allows us to count on an excellent team.

Complete supplies

Gatta welded structures include thermal treatment, machining and finishing.

Customer service

Fast estimates, flexible production and priority to customer satisfaction.

Quality

The entire production process is subject to quality control procedures in accordance with ISO 9001.

Mechanical electrowelded structures

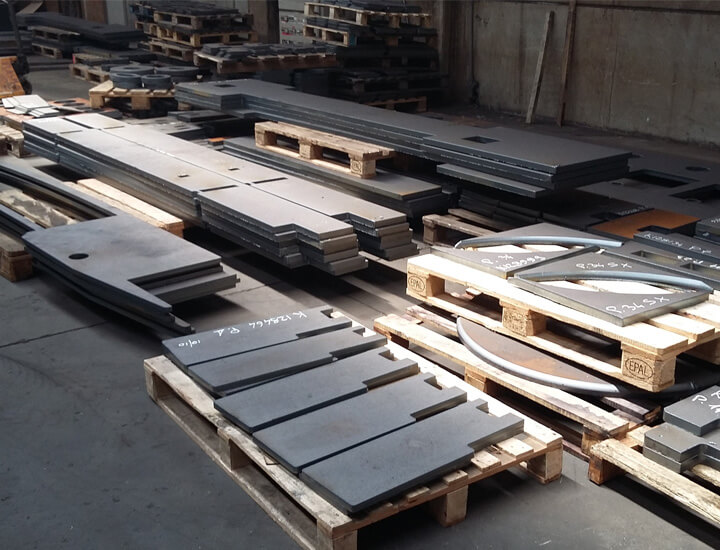

Materials

Thorough selection of raw materials and qualified suppliers. The main materials used are: carbon steel (iron), C40, Stainless steel, Special steels and Aluminium (all certified).

Fields of application

The firm’s consolidated experience and flexibility acquired over the years allow us to provide custom-built solutions for a wide range of sectors.

Machine tools

Shipbuilding

Other machinery and industrial installations

Thanks to the long experience of its staff, the Mechanical Carpentry department is ready to face new technological challenges

Experience and Technology

Discover our machining processes

Cutting

Sheet metal cutting with oxyfuel and plasma technologies. Sheet metal drilling and threading with dedicated unit.

Assembly

Assembly of semi-finished components according to the customer’s design.

Welding

Qualified welding processes: MIG, MAG, TIG with the use of the latest generation welding machines.

Finishing

Grinding and surface cleaning.

Treatments

Stretching, blasting and spray treatments with a base coat.