Bending Services

Your solution for bending

Versatility

Versatility guaranteed: diversified materials (steels, stainless steel, aluminium, copper, brass), thicknesses from 0.5 mm to 200 mm, air bending, bottom bending, coining and hemming

Flexibility

We guarantee a personalised service and the capability to fulfil urgent demand, seamlessly accommodating different orders with few or many article codes.

Speed

Estimates are provided quickly or sometimes instantly, thanks to a high level of process automation. Technical appointments within 24 hours, at our headquarters or at the customer’s company

Service

Technical support and customer service available. Production process compliant with ISO 9001 including quality control

Bending Services

Our “Service Centre” is a work environment designed to support firms that subcontract some of their processes, or need to carry out occasional production.

Bending is a type of manufacturing that involves the permanent deformation of the sheet metal by means of a bending action. The technical skill of the operators and the correct management of the equipment are crucial to ensure quality results.

Our operations team can offer custom solutions for a variety of customers and projects.

Bending Technologies

Air Bending

Air bending involves the use of a top punch that presses the sheet into a V-shaped die, leaving an empty space between the sheet and the bottom. This method allows the bending even of thick sheets, using less force, and to obtain different angles using the same tools.Bottom bending

With bottom bending, the dies allow overbending up to the maximum limit of the V aperture. This method guarantees precision and regular angles, reducing the elastic return, making the technique similar to moulding.Coining

Coining involves the use of a punch, which presses the metal sheet fully down to the hollow bottom of the die. By using the punch and the die with the same angle of inclination, the elastic return is completely eliminated. This technique offers precision, regular angles and the possibility of obtaining lower angles than with air bending.

Hemming or flattening

Hemming takes place in two phases: a pre-hemming followed by a flattening process when the metal sheet is hemmed completely or partially. This technique, used to obtain rigidity and protection on the edges, requires special presses and is used to avoid sharp edges on the metal sheet.

Principal bending machines

We constantly update our machinery pool, and invest in the ongoing training of our team to maximise the use of our resources and obtain optimal performance from our equipment.

Amada HG 220 4 ATC bending machine 220 T. / 4.00 m. – (Automatic Mould Change)

Amada HG 130 3 bending machine from 130 T. 3.00 m. C.N.

Amada Schiavi HFB 220 high light bending machine from 220 T. 3.00 m. – CN

Schiavi HFB 125 bending machine from 125 T. 3.00 m.- C.N.

Amada Schiavi STPC 303 bending machine from 300 T. 3.00 m. – CN

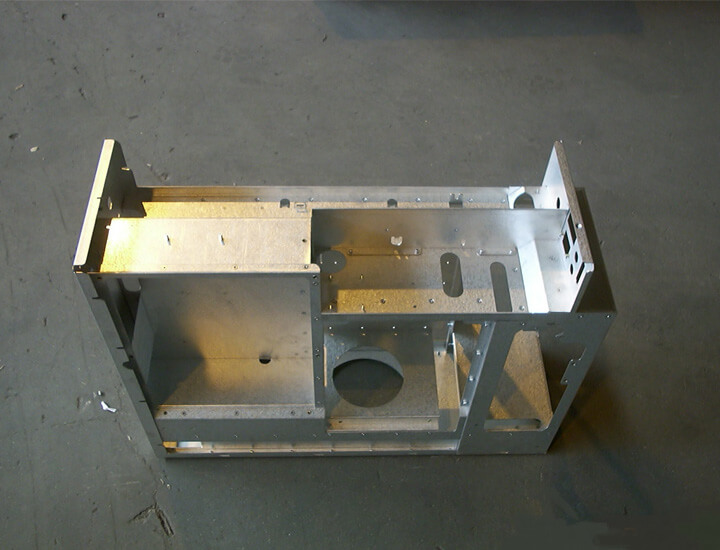

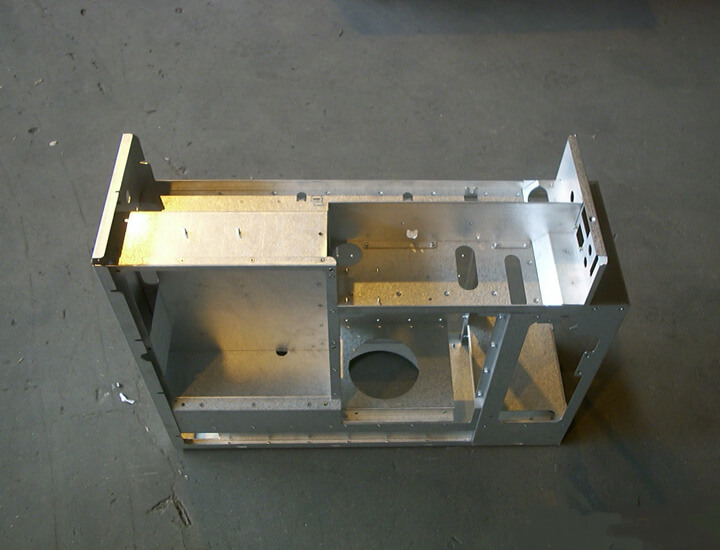

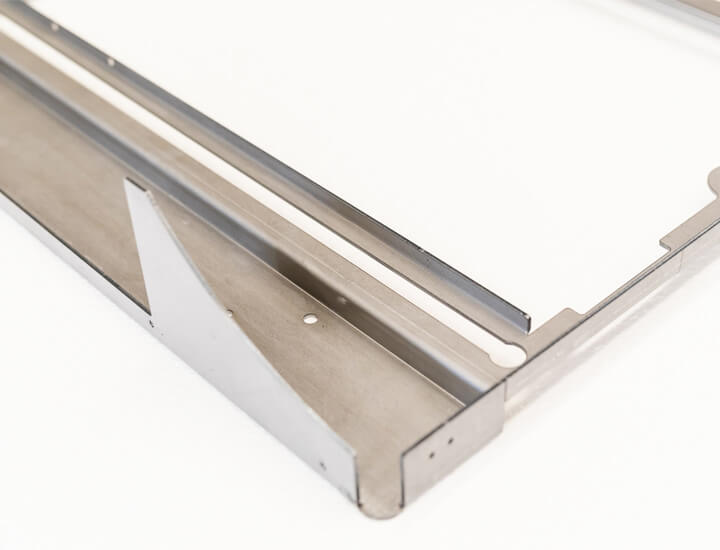

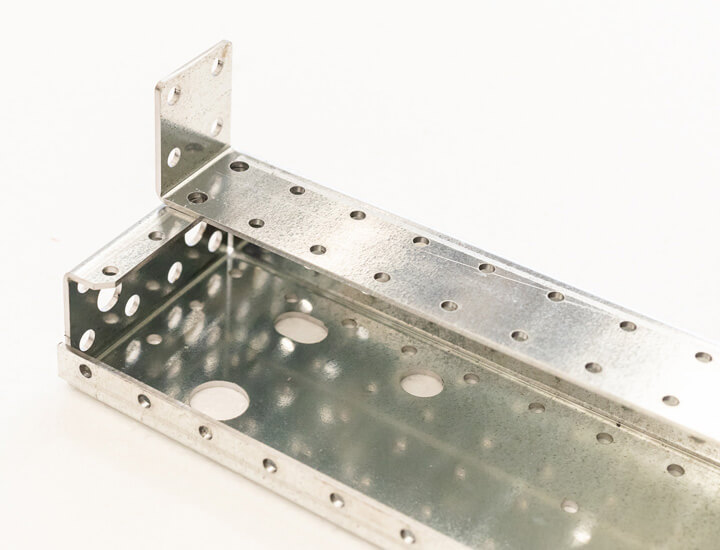

Some of our bent metal products

Our Services in Numbers

3.500 mq

department area used for the “Service Centre” on a site covering a total of 10,000 square metres, available to our customers

15

workshop staff working in support of various Service Centre activities

6

members of the Technical Office available to offer technical support and advice to customers

250 h/week

production capacity of our bending machines

6 h

maximum response time for preparing estimates

€1.5m

invested in new-generation machinery over the last 3 years